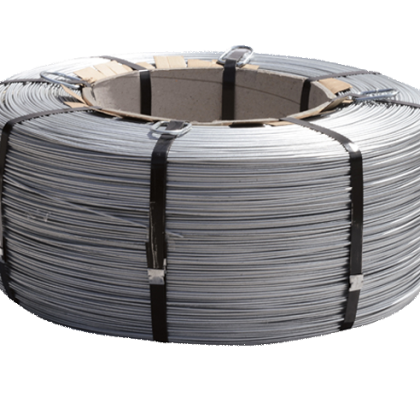

HOMOPOLYMER ACRYLIC FILTER BAG FABRIC

FABRIC QUALITY: HOMOPOLYMER ACRYLIC - DF 050 PE/AC

WEIGHT: 500 g/m2 (DIN EN 29073 – Part 1)

THICKNESS: 2.0 mm (DIN EN ISO 9073 – Part 2)

DENSITY: 0.29 g/cm3

AIR PERMEATION: 180 l/(dm2 .min) per minute (DIN 53887)

* 11,000 per hour – 14.000 l/(dm2 .hr) @ 200 Pa 5 cm

*(EXAMPLE MEASUREMENT 200/50 mm) DIN EN 29073 – Part 3

OPERATING TEMPERATURE: 140 C

HOMOPOLYMER ACRYLIC FILTER BAG FABRIC

FABRIC QUALITY: HOMOPOLYMER ACRYLIC - DF 055 PE/AC

WEIGHT: 550 g/m2 (DIN EN 29073– Part 1)

THICKNESS: 2.2 mm (DIN EN ISO 9073 – Part 2)

DENSITY: 0.29 g/cm3

AIR PERMEATION: 160 l/(dm2 .min)(DIN 53887)

* 9,000 per hour – 12,000 l/(dm2 .hr) @ 200 Pa

BREAKING STRENGTH: Transverse 165 kgf /5 cm Longitudinal 145 kgf /5 cm *(EXAMPLE 200/50 mm) DIN EN 29073 – Part 3

OPERATING TEMPERATURE: 140 C

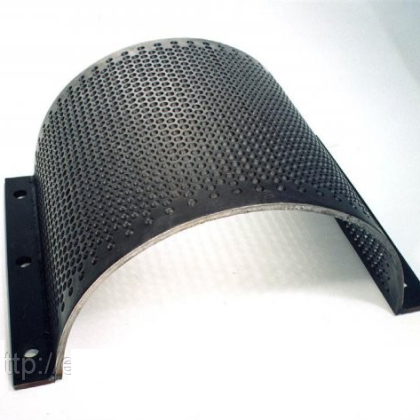

THE POLISHING PROCESS, WHICH WE CALL GAZE AND KALENDER, HAS BEEN PERFORMED ON THE FABRIC SURFACES.

HYDROPHOBIC IMPRINT PROCESS HAS BEEN APPLIED TO THE FABRIC, PROVIDING RESISTANCE AGAINST WATER AND OIL.

FRONT AND BACK SIDE OF ACRYLIC FABRIC DURING NEEDLEING ÇNEEDED DOUBLE SIDED.

IT IS ALSO INTERIOR OF THE FABRIC WHICH INCREASES ITS DURABILITY. TISSUE (SCRIM) HAS BEEN PLACED.

English

English

Türkçe

Türkçe