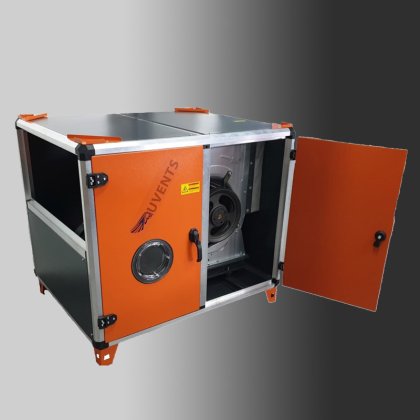

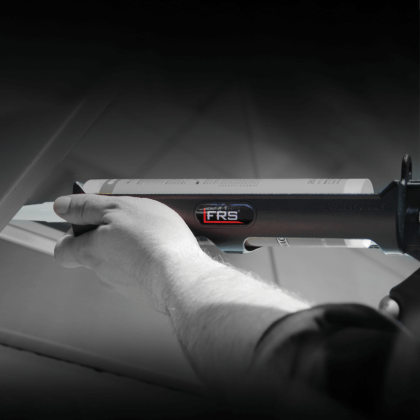

The SG-23 and SG-30 series medium sized breaking machines can be used to break the plastic parts and filters, which are produced in the injection, inflation or extrusion machines, either near the machine or centrally.

The SG-23 and SG-30 series breaking machines which are really easy to use internally with their durable structures and high level sound insulation property are a candidate in becoming one of the most effective devices in your business along with their other properties.

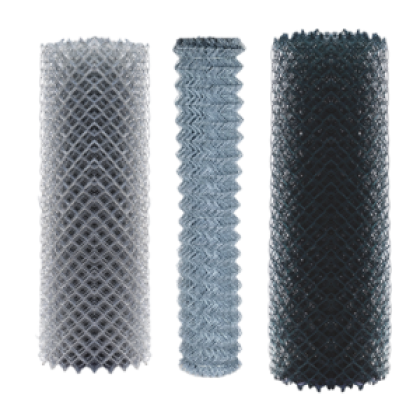

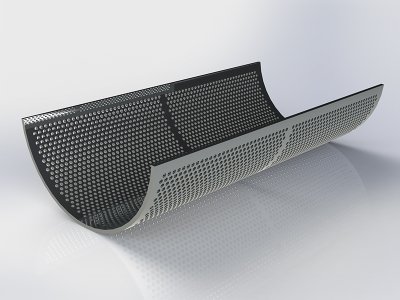

Cascaded Blade

Not only does the cascaded blade system ensure high capacity and low energy waste, but it also minimizes problems such as jamming and winding. Each one of the cascaded blades is 12 cm wide. The rotor width; there are 2 cascaded blades in the 24 cm model; 3 in the 36 cm model; 4 in the 48 cm models; and 5 in the 60 cm models.

Flat Blade

With the flat bladed system, it is really easy to break thin walled materials and inflating products. Also, the sound that is made during breaking is less thanks to the blade designs.

Standard Specifications

- Not only does the cascaded blade system ensure high capacity and low energy waste, but it also minimizes problems such as jamming and winding

- And the flat blade system is offered optionally to break the thin walled materials

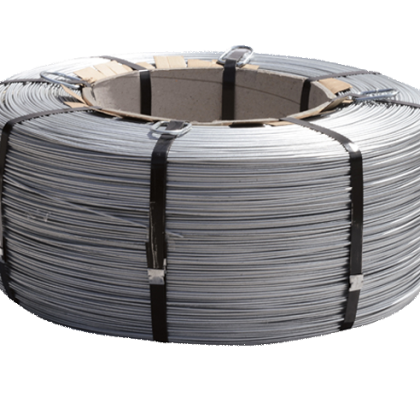

- The D2 hardness of the material of the blades is 58~60 HRC

- It has mechanical and electronic protection switches, and the German origin SCHMERSAL brand switch has been used.

- There are chamber opening and sieve protection sensors.

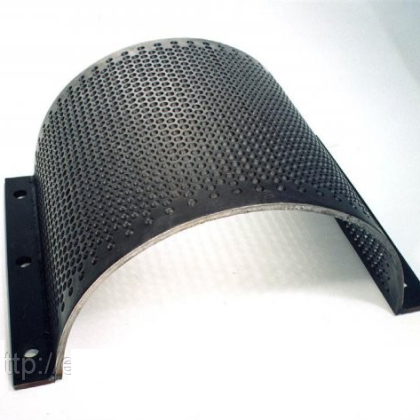

- It can be used bilaterally and there is a durable sieve that can be easily replaced

- It is highly efficient and durable with a Siemens / Weg motor.

- Belt and pulley system designed to provide a high breaking torque with low energy consumption.

- The main switch start/stop and emergency buttons allow swift motion with their ergonomic structures

- With the sieve box that can be opened downward and the upper chamber that is opened upward by means of the piston mechanism, the cleaning procedure of the cutter and sieve area can be performed quickly and easily

- The contactors are German made and Siemens brand

- Its cutter body is made of strong steel casting material

- Its spare parts can be found in HASTEK stocks

- Sound insulation design

- All parts comply with CE norms.

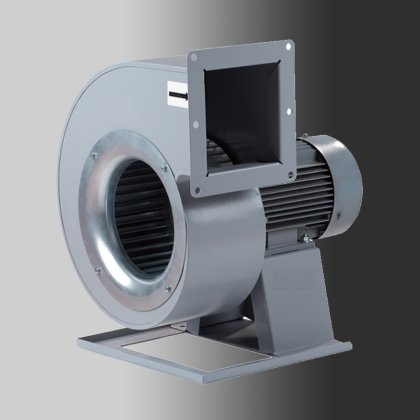

- Blower system that fills the broken goods into the silo

- The water cooling device at the back plate within the cutting chamber cools the cutting chamber and prevents the materials from melting.

- Stainless steel, metal clip magnetic wide feeding slot

- Stainless steel goods feeding chamber

Made from stainless steel, high-capacity accumulation area.

English

English

Türkçe

Türkçe