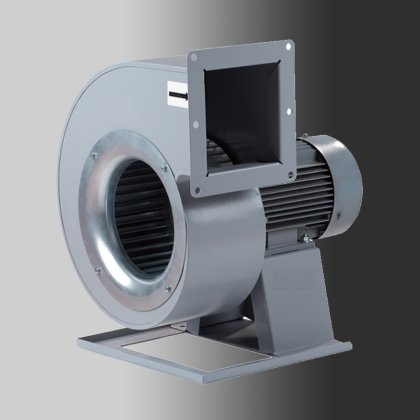

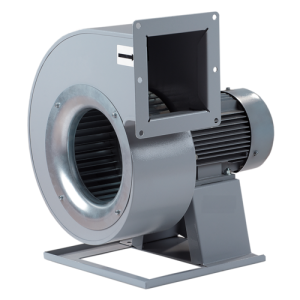

Dust Transfer Fans are the most important equipment of dust collection systems. Many factors such as the type of the dust, the specific weight of the dust, the granular size of the dust, the static pressure losses within the canals and the unit (pressure losses of the equipment, if any), the risk of explosion of the dust, and temperature should be taken into consideration while picking out dust transfer fans.

Centrifugal radial fans are used in dust collection systems. These fans are used as low, medium or high pressured, depending on the project and application.

The following should be considered when selecting centrifugal fans:

- There are three types of fans as direct-coupled, vee belt drive, and with coupling

- They can be made as low, medium or high pressured

- They must be placed on the end point of the channel system

- Tight-blade fans should be used as little as possible

- Measures must be taken against sparks and explosions in carrying explosive and flammable gases, in the fan blades and electric engines.

- The necessary measures must be taken against corrosion in the fan during the evacuation of the corrosive dust and gases.

English

English

Türkçe

Türkçe